Providing ISO 17025-accredited Cannabis Testing services to meet and exceed regulatory requirements for consumer protection: We Are Confidence Analytics.

Through scientific integrity and industry expertise, we provide Cannabis Testing and analytical services to benefit production and sourcing of products with true quality assurance and traceable documentation.

CANNABINOIDS OF INTEREST

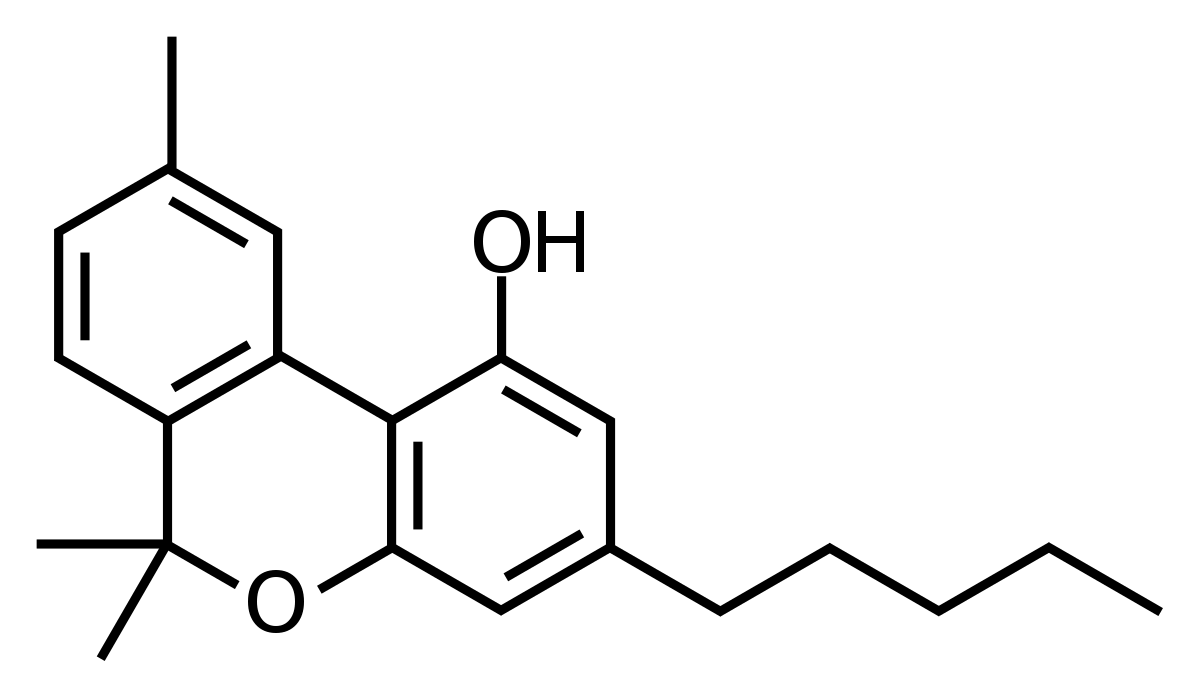

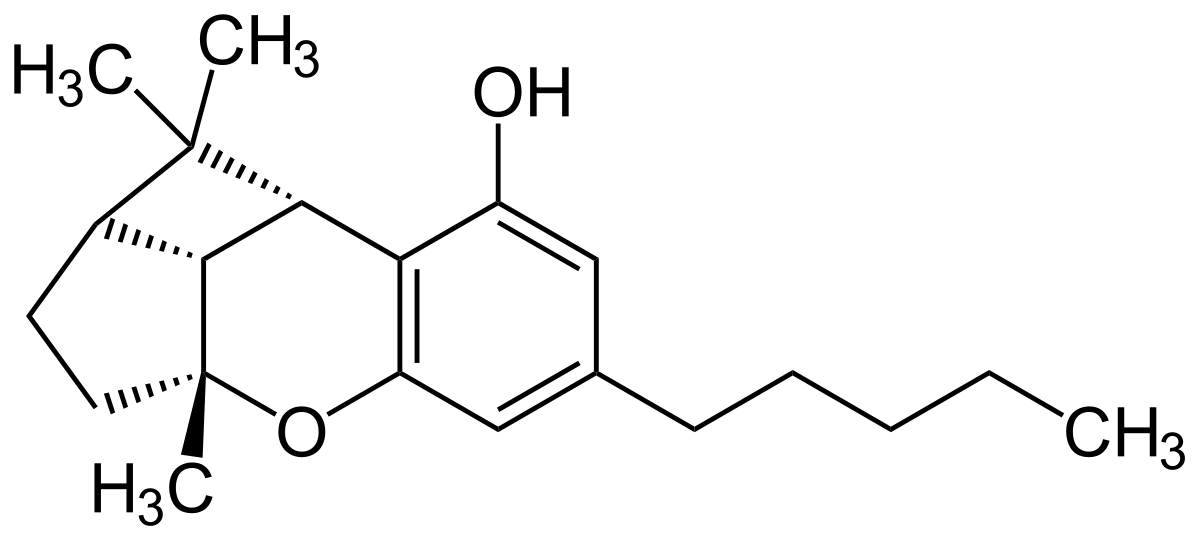

THC

Tetrahydrocannabinol

The compound most associated with the psychoactive effect

THCA

Tetrahydrocannabinolic Acid

The predominant form of the molecule in raw material

CBD

Cannabidiol

The compound most associated with medicinal properties

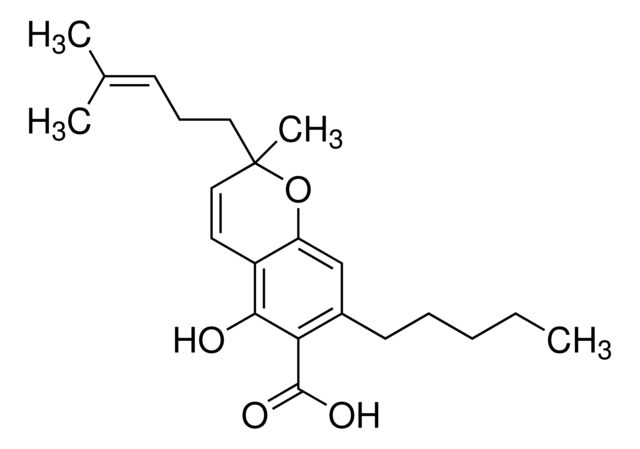

CBDA

Cannabidiolic acid

The predominant form of the molecule in raw material

CBG

Cannabigerol

The precursor to THC & CBD in the biosynthesis pathway; shown to reduce intraocular pressure

CBGA

Cannabigerol acid

The predominant form of the molecule in raw material

CBN

Cannabinol

The primary breakdown product of THC & CBD with known sedative and anxiolytic properties

CBNA

Cannabinolic Acid

The acid form of CBN.

THCV

Tetrahydrocannabivarin

Similar to CBD, THCV appears to modulate THC uptake

THCVA

Tetrahydrocannabivarin Acid

The acid form of Tetrahydrocannabivarin

CBDV

Cannabidivarin

Appears to have strong potential for treatment of epilepsy

CBDVA

Cannabidivarin

Appears to have strong potential for treatment of epilepsy

CBC

Cannabichromene

Has a suggested role in the anti-inflammatory, antiviral and analgesic effects of cannabis

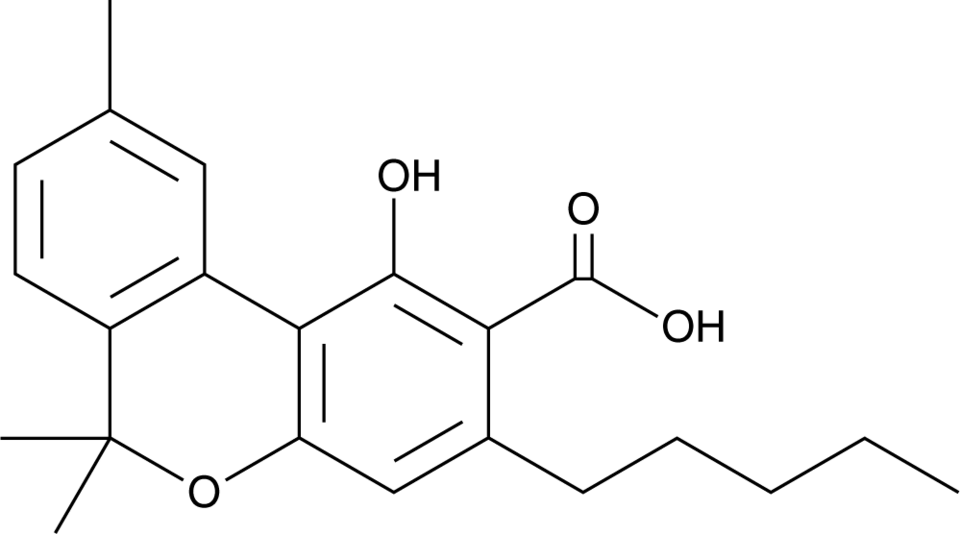

CBCA

Cannabichromic Acid

The acid form of Cannabichromene

CBT

Cannabicitran

Not psychoactive, but was found to reduce intraocular pressure in tests on rabbits

CBL

Cannabicyclol

A degradation product of CBC

d8-THC

delta-8 Tetrahydrocannabinol

A less psychoactive isomer of the commonly found d9-THC