At Confidence Analytics, we strive to understand more about Cannabis every day. Not only do we perform experiments to improve our procedures and data quality, but we have the opportunity to try new and exciting techniques in the laboratory.

This week, Molecular Biologist Levi Boss and Chemist Zachary Iszard bring you some preliminary results on a project that fascinates them: crystallization and isolation of cannabinoids.

In much of the chemical industry, recrystallization is used to achieve very high purity on a large scale without complex equipment. The target compound of interest, is dissolved in a specific solvent to form a solution. Low pressure and heat are applied so that the target compound crashes out of solution, or precipitates out as a solid. The target compound will prefer to stick to other molecules like itself, and will do so in an ordered fashion – forming a crystal. When a substance crystallizes, any impurities – which have different chemical structures – are excluded from the crystal lattice, simply because the impurities interfere with the tightly ordered structure and prefer to either remain in solution or self-associate. Examples of this process are the formation of rock salt and rock candy by evaporation. A Cannabis-specific example most readers are likely familiar with would be the winterization of concentrates by low temperature. In this example, the plant waxes and lipids are the target compounds. Evaporation and cooling are two different ways to make the target compound less soluble in the chosen solvent, and thus precipitate out.

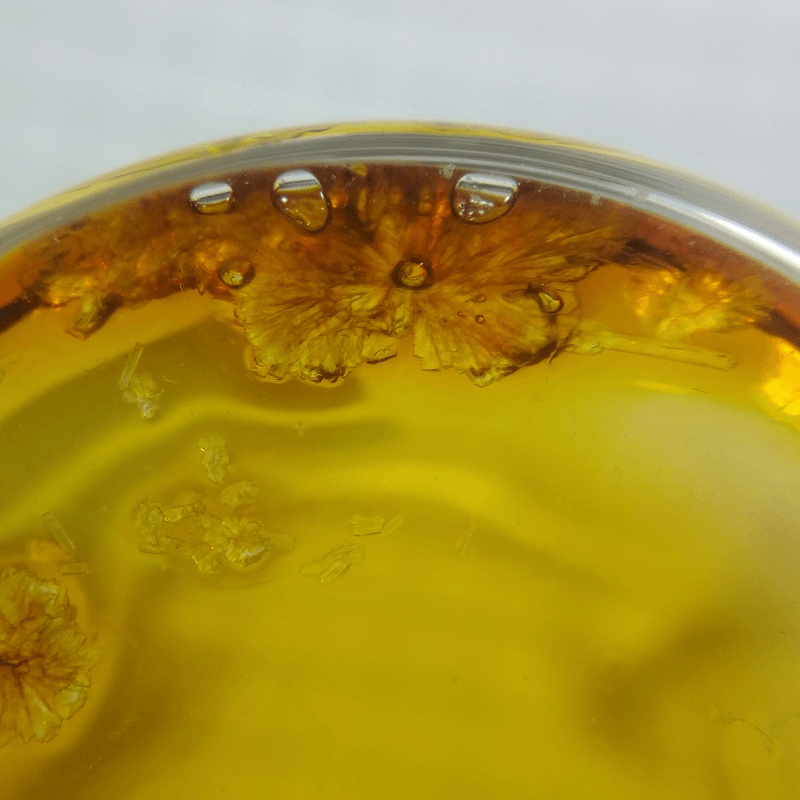

We found that a semi-solid CO2 oil (75% total cannabinoids) will form localized crystals at the bottom of a small glass beaker over several days under slight heat. The experiment was repeated and controlled using an ethanol solution highly saturated with CO2 oil, filtered through a 0.2 um nylon filter, and winterized. The results were pleasing: much larger and more numerous crystals!

We let these beakers heat at about 40°C (104°F) for another few days, and the crystals had indeed grown. We also noticed that the crystals had piled up higher than the surrounding layer of concentrate, and that bubbles had formed underneath these crystals. With a careful eye and a magnifying glass, it is easy to see that some of the crystals are colorless – a very general indicator of purity. We hypothesized that these bubbles were tell-tale indicators of decarboxylation of THC-A, since they increased in size over an extended period of time under testing conditions – hinting at a chemical reaction proceeding toward completion.

Samples were taken for HPLC potency analysis, and the results were promising. The crystal sample, though lower in total cannabinoid content, was enriched in THC-A compared to the surrounding material, which had a higher percentage of every other minor cannabinoid. This supports our hypothesis that THC-A is the material that is observed crystallizing. Since THC-A was the majority compound in the concentrate sample, none of this is terribly surprising. Because the crystals themselves were small, we couldn’t pick out only crystals for analysis, so our results are indeed imperfect.

The next task is to improve the crystallization method, and to form larger isolated crystals more quickly.

44 Comments on “Cannabinoid Crystallization”

Hello,

My name is Reese. I currently work in an extraction lab and was wondering what kind of ratio would your solution have to be? And does type of ethanol matter in process? Can it be done without a solvent?

Hi Reese

We did it without solvents to make this picture. Just slow heating and cooling in an oven over long periods of time. Perhaps not the most efficient way. We made THCA crystals by accident the first time! That’s been true for a lot of people.

Yes, it probably matters what solvents you use, and if you’re using solvent mixes, what ratios. Crystals will certainly form in a variety of solvents including ethanol, butane, and CO2. Which solvents or solvent ratios work best and at what temperatures remains an open question.

How do you master getting bigger crystals?

In short, go slower. The idea is to grow a small number of large crystals, so thorough filtration (to remove crystal “seeds” like dust and particulate) and slow temperature/concentration change (instead of rapid change) is better than just forcing it. You can also go in cycles for ultra-high purity: filter out lots of small crystals, wash them with saturated solvent solution over filtration, then redissolve them in minimum very clean solvent and recrystallize again.

There’s a lot more out there about recrystallization as a means of separation / purification. As long as you know your conditions — what solvent, saturated concentration (mass of stuff per volume of solvent), and temperature range gives you best results — the rest is all finesse and patience. It should be possible to get fist-sized single crystals of THCA …. but only with *very careful control* of the recrystallization conditions I named above.

What would be more efficient, a soak, or pressure?

Hey Bob,

Classically, in order to recrystallize a soluble substance, you first dissolve it in a minimum amount of solvent at relatively high temperature, and then slowly cool the solution until crystals precipitate. This assumes ambient pressure (1 atmosphere) the whole way through.

Broadly, you want to start with a condition where your solvent dissolves lots of your solute (say, THCA), and end with a condition where your solvent barely dissolves your solute, and traverse between start and end conditions very slowly and at a constant rate. If using CO2 or butane as the recrystallizing solvent, controlling pressure and temperature are both necessary because they are both gases under normal conditions. Ethanol behaves more “classically” in that ambient air pressure is good enough to keep it a liquid, and you can get a pretty wide solubility range using temperature control alone. I know with CO2 that “loading” (solvent capacity for solutes) is higher with higher CO2 pressure. Is this what you meant by pressure?

The short answer is I am not sure what pressure and temperature ranges for these different solvents will work best, but the mechanism of a solid recrystallization is careful control of the solubility of your target. If you can start highly soluble, and end poorly soluble, you will get crystals. The rest is finesse!

is there a detailed explaination of the process?? i know you learn all about crystallization but i want to see like videos of the process.. or pictures at least of stages..

Unfortunately we didn’t video the process or take any pictures – but there’s plenty of examples out there, most of them using copper sulfate. Here’s a nice concise one: https://www.youtube.com/watch?v=QdwKhbtzsug

Have you used the pure co2 oil crystals as seed crystals in another batch? You first made pure ones than you diluted in ethanol to get greater crystals. The pure ones seem to be immediately usable, while the ethanol grown will have to be purified? So two questions What would be the best method to get sheet tray like thca from ethanol grown crystals. And can I increase pressure on the pure co2 oil to achieve some sort of increase in chance to precipitate without increasing the temperature?

Hey Chronalc,

I’m trying to decipher your message. To make the crystals seen in this image, we winterized some raw CO2 in the classic way, and then finished the purge in our drying oven for many days at about 100 F. We did not start with crystals. The beaker image is zoomed in to show that recrystallization can happen, but we did not intend to recrystallize. The material there has very low ethanol content.

I’d direct you to read my reply to Bob above. The principle of recrystallization (how you make pure crystals from impure solution) is very old and well-described in other substances. Until a good recrystallization process is defined for THCA, I don’t think seed crystals will be of much use. I also cannot tell you what conditions are best to use (what temp, pressure, solvent, etc.) because I have not tried it myself. As far as changing the function of your CO2 system, I would ask your manufacturer how you may bring the pressure up at a static temperature. I imagine you would need a heat exchanger or radiator.

I encourage you to look through YouTube, chemistry text books, etc. to get a strong grasp on the principles; the way you approach a recrystallization will emerge once you understand how the process works.

After creating a seed in theory is it ideal to put into a super saturated solution to help grow larger lattice then filter and recrystallize?

Hi Reese,

In classical recrystallization, some solutions can become super-saturated. Large single crystals can be made quickly by carefully introducing a seed crystal to the otherwise undisturbed solution. However, not all solute-solvent systems will behave this way. If you are dealing with a large number of small crystals, try evaporating/cooling the solution more slowly. Also try starting with exceptionally clean containers to hold your recrystallizing solution, too, being mindful of every particle of dust and every fiber of paper or cloth. Once you have some large crystals, it is up to you if you want to lose more yield with another recrystallization.

Hope this helps!

Hey there I read a few of your responses about thca crystallization and I was wondering what direction you could point me in as far as learning what I need to know about making large crystals. You mention chemistry text book. Anything in specific?

thanks a lot for taking time to answer and undisturbed as in it completely cooled on its own, then introducing back into solution? Also with smaller crystals would dropping a few through out jar in help grow various in solution or concentrating into one area be ideal? thanks again for brain picking!

I’m curious on your method of removing ethanol while winterizing and still being able to keep mostly THCa without residual solvents. Can you elaborate on temps and such on that process a little more? What Co2 machine was this done on?

To chime in, recently made THC oil with ethanol and taking advantage of a cold winter day performed a winterization. Immidiatly moved this into a deep freezer to do its thing. Now I was using the ideal of recrystalization/cocrystalization. There where a lot of altering factors that could very well have caused the crystallizing I saw. First is there was activated thc, thca and cbd. Also it was 4 strains as well as one of the strains had previously been through a butter bath and another one has been through a green dragon tincture distilled in a mix of expensive gin and Absinthe. So with all these determining factors it is very hard to say. I unfortunately did not study enough to know thc responds with a red hue when attacked by direct light and that tichro’s look like floating fat in the frozen solution. Makes sense since they solidify like glass. But as the ethanol evaporated you could visually was a crystallization/scrubbing process happening and it all kinda freaked me out and I did not want thc oil with butter in it and messed the reaction up. I am hoping I can manage this reaction again. Now I am wondering if subzero decrab is possible as well as wondering How a battle between the three would turn out during a cocrystalization. That’s my 2 cents.

Great information! Thanks for sharing the knowledge.

Have you ever had issues with your crystallization where the constituency becomes chalky and unable to form crystal structure? It has to be some sort of contaminant but was curious if you ran into this during your experiments and if you knew of the likely culprit to cause the interference? Thank you!

We used a co2 subcritical extractor at 120 degrees / 2300 psi . Used a 50lb co2 tank, with a food grade alcohol.

Those are supercritical temps & pressures for Co2. Co2 becomes supercritical @ 31.1c or 87.98f & 1071psi.

saw this on instagram – same idea I think?

https://www.instagram.com/p/Bg6g99tD2UL/?taken-by=srene_nv

why was 106 F used? Why not 100…or 130? Just curious how you settled on that number for crystallization.

That just happened to be the reading that we got from the oven when it was set to ~100F, nothing more designed than that!

Thank you so. Much for the information, this has been The best I have found.

So can a regular oleo resin such as rosin, or even bho be winterized, in a regular freezer well enough?

Also.. Can i use ethanol, or isopropyl, to recrystallizate cbd isolate powder?

Hello,

I am trying to get my concentrate to not crystallize when in my cartridges. I’m no chemist and do not work in a lab. Just want to turn my concentrate into a viscous oil to vape discreetly. Right now I use terpene oil to dilute. Regardless of concentrate, I get crystals or what looks like a waxy substance falls out. Not sure if any are winterized or what. I get it if I can’t do this in a home environment but it would be nice if I could.

So I’m curious what pressures is the material under during the testing on solventless I’m currently working on this method and would like to try and narrow down a exact pressure so I can build a regulator to keep the consistent pressure

This was all done at room temperature!

I was hoping you could answer a question for me: What type of mixing soultion (PG/VG/MCT/terps/other) could be used in vape pods/cartridges in order to keep the CBD from crystallizing ? Thank you!

Hi there I am from SA. What is the best way to winterize CO2 wax.

Regards

Elize

Can anyone tell me why my crude oil from extraction machine is turning black almost immediately after harvesting it from the collectors? Never had this problem until after I started to decarb the grind material.

Without more information on your extraction machine, this sounds like you are extracting more chlorophyll and other pigments in your crude oil. Assuming you are using ethanol, try chilling it before extracting should help some (ideally you would extract with -20C). Realistically, you will probably need to clean up your extract post-extraction with a product like CarbonX. Activated charcoal can also work but can also deposit heavy metals into your extract due to it being made from natural sources. Hope this helps!

So I can take a crystal and put it in a fresh batch and they will grown faster?

So I can take a crystal and put it in a fresh batch and they will grown faster

I’m a chemical engineering technology student working on my technical report and looking to try some different concentrate methods. What sort of equipment would be needed to produce THCA from a BHO sample.

I really appreciate this post thank you for sharing these type of posts

I’ve been adding seeds to jars of runs still heavy with butane and leaving i. Freezer and lots of smalls crystals spread fast in a week or two but how can i grow them larger ?? Take out of freeZer? Any tips

You can try. Butane extract then purge in vacuum pump tell its completely purged then place in a clean jar and dissolve that ball of wax you just purged into rubbing alcohol for a winterizing process for 48 hours then take off lid filter out the fats and waxes using a coffee filter. Then let the filtered solution set with no lid tell rubbing alcohol solution turns a thick syrup then poor acetone into the now thick solution place a lid on and put in the dark undisturbed for 2-3 week take out after the week are over and under the wax solution should of formed crystal pur out the liquid pick out the seed crystals place in a new clean glass with a little acetone dissolve the seed crystals into acetone to get your crystals repeat using same Crystal to make bigger and bigger you just need to keep saturating heavy in your solution before repeating and placing your crystals back in for more growth.

What is a solution to keeping the distillate liquid. I need my distillate to stay liquid and not crystallize. Does anyone know a mixture or recipe to avoid this?

How can you tell the difference between a thc cart and a cbd cart?

Pingback: Can CBD Oil Go Bad? - Slyng.com

The lab I worked in had issues with the process of CO2 extraction leading to a signifigant amount of THCa to decarb under the pressure and heat. Does THC still crystalize? I am under the impression it does not. And do you ever have issues with there being ethanol in large crystals?

@Zack the Chromatographer

Great article, thank you very much.

To all the guys who dont quite get it, try the procedure with salt and water. try to grow salt crystals as a basis to understanding. good luck.

I left a jar 99% isopropyl alcohol for like 3 years in my basement. Sometime within the last few months I’m guessing the lid got removed from the jar and today I found what looked like about a quarter ounce of THC crystals in the bottom of the jar. However upon trying to vaporize them they do not melt. They taste just like THC crystals should taste but no vapor or smoke comes off from them even in a very high temperature. Would you happen to know the explanation for this phenomenon?

Sorry I forgot to clarify in the above comment The jar was used for cleaning glass pipes many many of them so there was a ton of resin in it and somehow crystals forms I wish I could attach a picture. They’re pretty much clear with what looks like turp sauce, a golden like residue on them

So if I’m reading everything correctly your process was like this.

1. Take plant matter run it through a closed loop C02 extractor

2. Take crude extract winterize it.

3. Take purified extract and use a solvent such as ethanol. than heat for at least 4 days at 104 degrees.

I was going to use pentane would this have a different boiling point for crystals to crash out. Also how much material are you losing with this process did you test to see how much THCa was still left in solution thanks.